A few years back, the good folks at Central New Mexico Community College told us all about their grand plans for a proper brewing school program.

We had high hopes, but there was no way they could pull off everything they discussed with us, right? Well, this past Friday, I met up with lead instructor Antonio Fernandez for a tour of the completed facility in the RPM building on the main campus.

It is everything they once envisioned, and more.

Fernandez, who was previously an award-winning head brewer at Ponderosa, took the job coming out of the pandemic shutdown. It’s now becoming what he hoped for when he took the post.

“Everyone that’s graduated from the program since I started here are now, they’re all working at breweries,” Fernandez said. “We’re operating at a nearly 100-percent employment rate for our graduates. Like everyone else, the breweries need labor. Everyone is looking for workers. It’s a great thing going on between us (and the industry) here.”

Our tour began in the large production room, filled to the brim with equipment in all directions.

“Here’s the heart, we’ve got four basically identical brewhouses,” Fernandez said. “They’re all 3-barrel, two vessels, but they are designed to do step mashing or even decoction. We got a little extra stuff built in to have that capability to do it, which is pretty cool.”

Among the recent beers brewed by students were an Italian pilsner (naturally, since their instructor won two gold medals for his version at Ponderosa), a schwarzbier, and a saison.

“Each (brewhouse) has its own grist case,” Fernandez said. “We have two separate augurs on the mill. What we can’t do is mill grain for all four brewhouses at the same time. That’s not a big deal. I can’t ever imagine where I’d be able to supervise four groups milling at the same time, anyway.”

Towering over the brewhouses were two special tanks.

“We’ve got a 30-barrel hot liquor and 30-barrel cold liquor tanks that can be refilled at the same time,” Fernandez said. “We can be refilling with 42-degree cold water and 175-degree hot water at all times.”

Yeah, a lot of breweries will be jealous of that.

“Fermentation row, we have six 3-barrel fermenters and six 6-barrel fermenters, all designed for single and double batching, or oversized batching,” Fernandez said. “The (brewhouse) kettles have a little capacity for over three barrels. We learned that the hard way. We overflowed the first couple (fermenters) when we were transferring. A little mess to clean up.”

We walked past some of the winemaking equipment, because yes, they have added that to the program, too. I spotted a familiar-looking piece of equipment amid the wine tanks.

“My little CIP tank, which needs to be decorated with Star Wars decals at some point,” Fernandez said. “It’s a perfect little R2D2.”

After we walked past three 3-barrel and three 6-barrel brite tanks, there was a shiny new piece of equipment that should stand out not just to future students but their future employers.

“This just got set up last week,” Fernandez said. “A Wild Goose Gosling single-head canning machine. It worked great. We got really good results. Now I can add packaging into the curriculum now. Which is going to be excellent. Almost all of our graduates have started out on the packaging line. This is probably going to be some of the most valuable stuff for them (to learn).”

Behind that was the spacious walk-in cooler.

“This is a cold room twice as big as the one I had in Ponderosa,” Fernandez said. “We’ve got three-tap towers installed in the other classroom. We’ve got a line that can be easily switched over to nitro. All you have to do is disconnect the CO2 line. Eventually we’ll start filling all of this stuff up.”

Returning to the main room, we came upon the classroom area just off the production floor, with long tables and chairs, a video screen, and more.

“We do a lot of back and forth all day,” Fernandez said. “It works pretty good to have it in the same spot. It’s wireless to my laptop. I’ve got a microphone in case stuff gets too loud, which happens when one or more brewhouses are running.”

Right next to that is the laboratory.

“Here’s our micro lab” Fernandez said. “We’ve got all the fun toys. Alkalizer, the densometers, (and) of course my espresso machine.”

Nice work there, professor.

“This is pretty fun, I got us a good deal on a QPCR testing machine, testing for wild yeast, bacteria,” Fernandez said. “Or, if we wanted, we could even do COVID tests on it.”

Much of the lab equipment was so new that they have not even used it yet, such as a fume hood. Odds are, they will use it this fall semester.

“What the curriculum was when I got here to now is changing every day,” Fernandez said.

We ducked outside for a moment to see a large, currently unused patio. Fernandez said they hope to find a shade structure, so they can make use of all the furniture currently packed into a storage area. Then, in the future, they can hold special events outside.

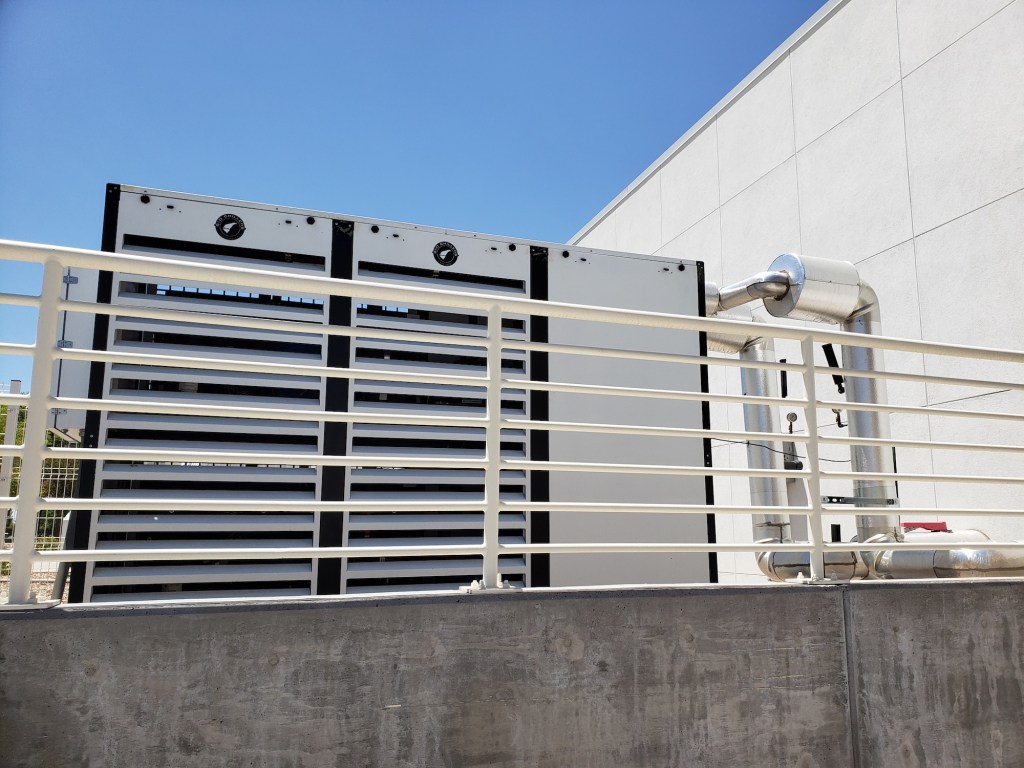

Right next to that, a large glycol chiller was humming away.

“Students have to learn how to take care of it, and they definitely learned over the past couple weeks when it went down due to the extreme heat,” Fernandez said.

Plenty of breweries have faced the same issue this summer, so that is good (if unfortunate) training.

We popped into a storage area next, where the hop pelletizer is waiting for this year’s harvest, which Fernandez said is coming earlier due to the heat.

Just outside of there is the electric forklift, parked next to the large garage door that can handle large-package deliveries, such as grain bags and other equipment.

Right next to it were a couple of wooden barrels, adorned with the signatures of the distilling program students.

“Those are the first couple barrels we’ve filled for the distilling program,” Fernandez said. “That one has bourbon, that one has single malt. It was just filled in April. In a few years, about the time I’m ready to retire, those will be ready to bottle.”

A temperature-controlled storage room was next, filled with empty kegs with CNM logos, and other items for future use.

“Those are all the CNM kegs, we’ll never need that many,” Fernandez said. “Eventually when we get our license, we’ll start getting some beer out in the market.”

We passed the combo still that is the heart of the distilling program. It can make everything from bourbon to vodka to gin to agave spirits.

After that, we exited out to the main hallway of the building, where they had set up some comfy chairs and tables into a nice lounge area. We walked around the corner and into a large classroom.

“All of this is the new construction part of the building that they added on,” Fernandez said. “Right here is where the old building ended. This is our only main classroom. This is our sensory lab. It’s where we hold the styles classes.”

Along one wall is a sign that reads Beverage Library. Inside were a lot of wine bottles. A whole lot.

“It’s always cool to have a wine cellar,” Fernandez said. “We have an 800 bottle capacity, not that we’ll ever need that many.”

Up at the front of the classroom, behind the instructor’s table, were the three-tap draft towers that Fernandez said were connected to the cold room in the production area.

“It’s really good, because we have a dedicated draft class,” he said. “They learn about the cleaning, setup, maintenance, design. They all come out of here knowing how to clean long-draw draft systems.”

After swinging through the culinary program’s rebuilt kitchen, we visited two more storage rooms. One was filled with beers of various classic styles, from German bocks to American pale ales, for the sensory/styles classes, and a few cheaper beers that are used for the off-flavor courses. The second storage room was filled with spirits of all types for the distilling program.

“We had a really good turnout for the distilling program classes,” Fernandez said, and I could see why.

After that, and a couple more photographs, we were done. Simply put, it is one of the most impressive breweries I have seen put together in New Mexico, a true purpose-built facility. And yet, it is not for commercial brewing, but instead to train the next wave of future brewers, cellarpersons, packaging line techs, and more. Our state has come a long way in terms of the quality and quantity of our breweries, and now it has the educational/training facility to match that.

Oh, and I did try the three beers they brewed during the summer session. All were high-quality ales and lagers, so give yourselves a pat on the back, CNM students.

All brewing classes are now open for the fall semester, which starts on September 5 (a week later than the rest of CNM). If you are interested, head over to the CNM website. Classes are even open to existing brewery employees, if they should wish to further enhance their skills in certain areas. There is also a Facebook page for the program that constantly posts updates.

We will be sure to check in with Antonio again, and maybe take a future look at the facility in action during the upcoming semester. A big thanks to our old friend for the tour, we were definitely overdue to take a look inside.

Cheers!

— Stoutmeister

One Comment Add yours